The new K52 integrated Argon Triple Point Cell and Maintenance System puts the user at the center of the design, making it easier than ever to realize this Primary Fixed Point. The geometry and system specifications expand on the capabilities of Pond Engineering's proven K38 Argon system, based on Furukawa and NIST Technical Note 1265 for cryogenic fixed points.

In normal operating mode, a 2-line LCD presenting the system setpoint and current measured temperature updates the user on system performance every 3 seconds. Interactive controls on the sloping front panel give the user easy access to all system functions, variables and diagnostic information. The integrated microprocessor-based digital controller provides standard user prompts to step through triple point realization and may be customized for special applications. Optional IEEE-488 or RS-232 remote interfaces, installed at the factory, allow users to configure the Argon Cell as part of an automated calibration system.

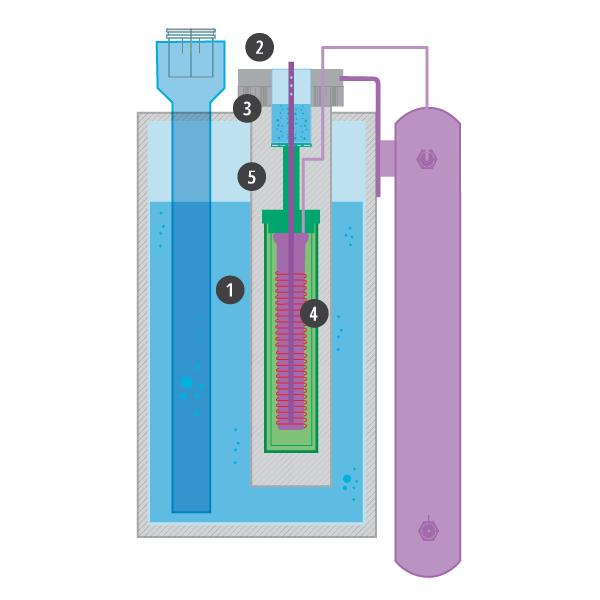

A sealed cryogenic triple point cell, containing .999 999 pure Argon, suspended in vacuum and surrounded by multiple copper thermal radiation shields with active thermal control ensures consistent, flat temperature plateaus with the capacity to realize the Argon triple point with an uncertainty better than +/- 0.000 25 K. The system is suitable for calibration of capsule- or long-stem Standard Platinum Resistance Thermometers (SPRTs). The Type 304 Stainless Steel thermowell passes through the liquid nitrogen in the internal dewar before entering the Argon sample, providing excellent thermal guarding. An integrated liquid nitrogen pumping system maintains a constant liquid nitrogen level above the cell without requiring user attention. A single fill of the internal 8L nitrogen dewar lasts up to 16 hours. Periodic refilling extends the plateau. An automatic filling system refills the internal liquid nitrogen dewar from a remote liquid nitrogen source for extended or continuous operation.

Users are walked through a standard realization procedure by integrated system prompts. Responding to a system prompt, the user initiates an automatic freeze cycle, flooding the thermowells with liquid nitrogen. This unique flood-and-freeze design removes heat directly from the Argon sample, providing a complete freeze in just 2 hours. Multiple thermometers may be calibrated in a single freeze cycle (from two to more than five depending on thermometer type), providing the capacity you need to meet your customer demands.

Or Contact Us for Additional Information.

- SPECIFICATIONS

- KEY FEATURES

-

Sample Purity 99.9999% Typical Plateau Duration >16 hours on a single fill of the internal LN2 storage dewar Thermowell Type 304 Stainless Steel

≈0.325" (8.2 mm) dia.

≈16.8" (427 mm) deepImmersion Depth ≈7" (18 cm) from liquid

sample surface to well

bottomOperator Interface Manual Front Panel

(optional IEEE-488 or

RS-232 remote)Power Requirements 90-264 Volts

1.5 Amps max

A.C. 47 - 63 Hz.Cabinet Physical Dimensions 18" (46 cm) wide

20" (51 cm) deep

36" (92 cm) high -

1. Internal 8 liter Liquid nitrogen dewar holds enough LN2 to realize triple point conditions and maintain a plateau for 16 hours 2. Unique flood-and-freeze design removes heat directly from the cell, reducing freeze times 3. Mechanical LN2 pump controls liquid level above the cell at a constant level and allows automatic operation of the freeze cycle, minimizing required operator intervention 4. Electric heater in thermal contact with the cell body forms outer melt and may be configured to periodically apply a heat pulse to confirm maintenance of triple point conditions 5. Copper thermal guard shells maintain an isothermal environment for extended, flat temperature plateaus